PLC and HMI Training for Industrial Automation

PLC and HMI Training for Industrial Automation is important for industrial automation learners. Now we are discussing PLC and HMI training systems. A program in industrial machine code that is loaded into PLC systems and represents the controlling program instructions as a sequence of binary code in numbers. The assembly language is based on mnemonics, and the mnemonics are translated into machine code by a computer program called an assembler.

Human-machine interface software is a type of programming that allows operators to manage machine control panels by providing information to them. In general, programmers create Human Machine Interface (HMI) software for machine control with appropriate applications. Bangladesh Automation Technologies offers extensive programming training for PLCs and HMIs.

What are Industrial Automation Courses?

This online course covers PLCs, Field Level Instrumentation, and SCADA/HMI Systems, all of which are used in industrial automation. Participants will gain appropriate knowledge and exposure to industrial controller configuration and application program development using IEC-61131-3 PLC languages. Interfaces with SCADA/HMI systems for remote monitoring and control of industrial process units and machines are also covered. Instructor-led live sessions of lectures and demonstrations are planned for the course.

What will you learn in industrial automation courses?

- PLC Basics & SCADA Basics

- Instructions in PLC & SCADA

- Distribution Control & Monitoring system

- Process Technologies

- Plant Automation

- Embedded training

- SCADA Training

- HMI Training

- PLC Training

Industrial Project

Through this course, you will be able to get a good idea about industry development. It has many roles in the development of industrial projects. Industry automation refers to the automation of industrial work/processes to increase production volume or quality. The use of automatic machinery or robotic arms is not required for industrial automation. It could also be as simple as adding a conveyor belt to speed up internal goods movement or using two workers instead of one on a time-consuming task to boost output. Industrial Projects | Industrial projects are the best way to understand industry automation.

VFD Training

Eaton’s goal is to improve your product knowledge, troubleshooting skills, and ability to safely operate Eaton variable frequency drives to accomplish this, Eaton provides self-guided, e-learning, and instructor-led training. Use the links in the training documents list to get a complete overview of the solid-state motor control training program, instructor-led training schedules, sign-up instructions, and more information about Eaton’s variable frequency drives training. Students will learn about variable frequency drives and how they are used in industrial plants and commercial buildings in this Variable Frequency Drives course. Students will learn how to improve VFD control and efficiency, troubleshoot and repair VFDs, reduce equipment downtime, and eliminate long-term VFD issues. Students who complete this online course will learn how to reduce the cost of running a VFD. There are no prerequisites for this course.

SCADA Training and HMI Training

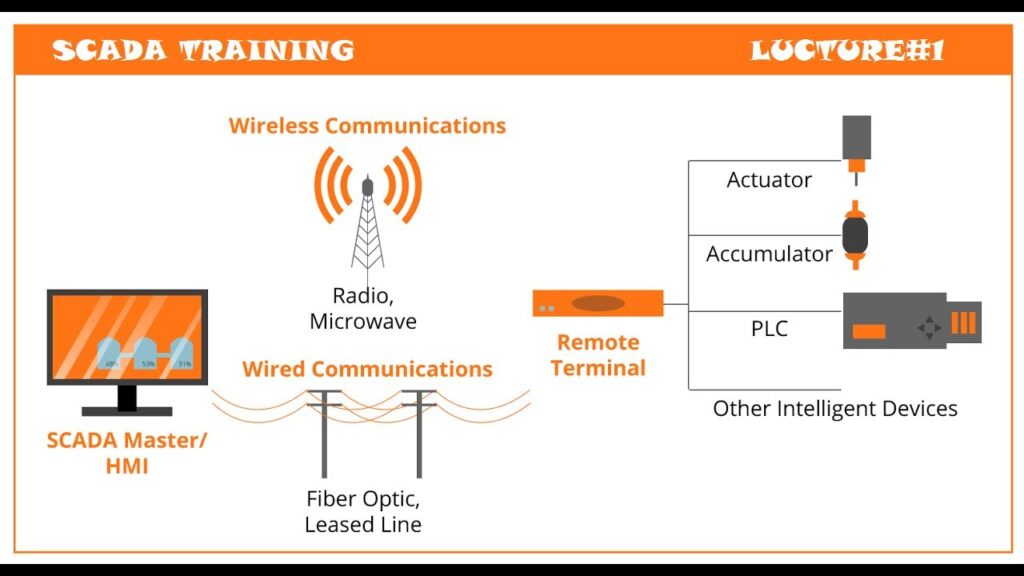

If that’s the case, you’ll want to learn more about supervisory control and data acquisition SCADA and programmable logic controllers (PLCs) (PLCs). SCADA is a real-time data collection and analysis computer system. Taking a SCADA training course can be beneficial in a variety of fields.

Supervisory control and data acquisition is a control system architecture for high-level supervision of machines and processes that consists of computers, networked data communications, and graphical user interfaces. It also includes sensors and other devices that interface with process plants or machinery, such as programmable logic controllers.

The SCADA computer system manages the operator interfaces that enable monitoring and the issuing of process commands, such as controller set point changes. Networked modules connected to field sensors and actuators perform subordinated operations, such as real-time control logic or controller calculations. The SCADA concept was created to provide a universal means of remote access to a wide range of local control modules from a variety of manufacturers using standard automation protocols.

In practice, large SCADA systems have evolved to function similarly to distributed control systems, utilizing multiple plant interfacing methods. They can control large-scale processes involving multiple sites and can work over long and short distances. A degree, computer skills, and experience are all requirements for becoming a SCADA engineer. Electrical, mechanical, industrial, or computer engineering are all options.

Human Machine Interface is computer programming that allows users to control machine command panels. A graphical user interface (GUI) is used to facilitate information exchange and communication between two types of HMIs: supervisory and machine level HMIs

How to learn HMI programming and development?

Any modern industry cannot function without industrial automation. Despite this, the growth of expertise in this sector is almost non-existent, which is a source of concern for our economy and industries. Our industries require a foreign consultant for basic industrial automation due to a lack of expertise. We have the opportunity to reverse this trend by developing our own skilled work for BCSIR’s PP & PDC, a Ministry of Science and Technology organization that has been offering a comprehensive training program in “PLC & HMI FOR INDUSTRIAL AUTOMATION.” This program has been designed and modified to provide industry expertise to engineers and technicians. You can learn many things from our comprehensive training, such as.

- Install the software and become familiar with it

- Create basic input and output structures tied to a PLC-based process.

- Explore intermediate functions of an HMI terminal.

- Work on both your design skills

Participants

Engineers, scientists, and maintenance managers/supervisors in production/manufacturing/chemical process plants such as power plants, paper mills, textile mills, sugar mills, water treatment plants, food processing plants, steam generation plants, various chemical process plants, and nearly all industrial plants. This program can benefit managers who work in the marketing of industrial automation instruments or the design of automation systems. job seekers want to who pursue a career in this field should be helped. For this program to work, you must have a basic understanding of electricity.

Course Content

- Interfacing of various switches and sensors in an industrial setting.

- Using the following, describe and design control circuits

- Electrical wiring

- Switchgear and control.

- Programmable Logic Controllers

- Various Motor and their Control

- Human Machine Interface

- Practical training on various machinery existing on the premises.

Conclusion

Bangladesh Automation Technologies is the leading organization in Bangladesh. Those who would like to work in the industrial automation sector must learn PLC and HMI Training for Industrial Automation. We are offering a comprehensive industrial automation course. Basically, our training system is based on the practical controlling system. It means how does an engineer practically works in the industry. We highly qualified teachers and a good environment, and also have other opportunities. We are pretty sure that if you come to Bangladesh Automation Technologies and do our course then it will be very beneficial for you.