Define PLC. How to Connect HMI to PLC?

Introduction

Welcome to another informative blog post from Bangladesh Automation Technologies. Today you will learn about PLC and connection of HMI to PLC.

In the field of Automation, PLC is a kind of electronic device which is used in the industry and factory for the purpose of controlling machine. In the automation field, it is also known as an electronic computer. The maximum industry and factory are now depending on the automation system.

Programmable Logic Controller (PLC) is an industrial solid-state computer which is monitors the input device and makes logic-based decisions for automated processes or machines.

Today’s, the maximum number of PLCs is a module. It is enabling the user to add more extra features such as including discrete control, analog control, PID control, position control, motor control, serial communication, and high-speed networking. If we compared to this PLC into older technologies, the PLC is simple to troubleshoot, more reliable, more cost-effective and more multipurpose.

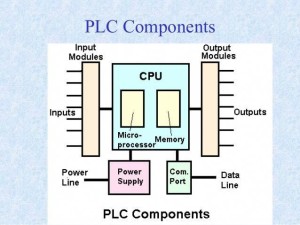

Basic Components of a PLC

A PLC basically composed of a few parts. It consists of a power supply, a central processing unit or CPU, input/output cards, and a backplane, carrier, or rack that these parts are placed into.

Power Supply

The power supply gives power to the PLC system. The power supply gives interior DC current to work the processor logic hardware and input/output assemblies. Normal power levels utilized are 24V DC or 120V AC.

Processor (CPU)

The processor, focal handling unit, or CPU is the “mind” of the PLC. The size and kind of CPU will decide things like the programming functions accessible, the size of the application logic accessible, a measure of memory access, and preparing speed. Understanding the CPU can be a complex subject and we will handle that in different articles.

Information/Output Assembly

Inputs convey signals from the procedure into the controller; they can be input switches, pressure sensors, administrator inputs, and so on. These resemble the faculties and sensors of the PLC.

These are the actuator the PLC can change to modify or control the procedure- engines, lights, transfers, pumps, and so forth.

Numerous types of inputs and outputs can be connected with a PLC, and they would all be able to be partitioned into two enormous gatherings- simple and digitalized. Digitalized inputs and outputs are those that work because of discrete or twofold change- on/off, yes/no. simple inputs and outputs change ceaselessly over a variable range- pressure, temperature, and potentiometer.

Programming Device

The PLC is programmed utilizing a claim to fame developer or programming on a PC that can load and change the logic inside. Most present-day PLCs are modified utilizing programming on a PC or PC phone. More established systems utilized a custom programming device.

How to Connect HMI to PLC?

It is been quite a while since we post the last communication model.

And this time, taking advantage of the new coming soon arrival of DVS and new DVP-SE, we choose to tell everybody the best way to impart one PLC and one HMI through Ethernet.

Incidentally, we are intending to put all communication interfaces in a single page to effortlessly connection to everybody.

Movement Control: HMI – PLC – B Series Servo (1 pivot developments)

There are a few different ways to control one pivot.

Yet, if you have to control position, the step and direction way is ordinarily the most simple and least expensive way.

The other benefit is that you don’t have to rack one’s brains thinking if that convention is getting down to work or not, Step and direction are all universal.

So our expectation in this post is to show you the Delta PLC devices to control one axis trough step and direction:

Equipment

As consistently the first is the manner by which to associate everything.

To communicate PLC and HMI you can check the HMI– PLC communication model.

Configuration

Fundamentally the configuration of the servo comprises in coordinate the servo contributions of the chart with the inner configuration.

Software

When the equipment and configuration are done, at that point you just need to download the following examples of HMI and PLC programs.

In these models we utilize three sorts of movements:

Relative Movement (DDRVI): We can move our servo some separation without sparing any reference.

Supreme Movement (DDRVA): We can move our servo some separation continually having reference where the house is.

Speed Movement (SPD): To keep up the servo at a steady speed. It is valuable for material taking care of applications.

One Axis Movements

All the Delta servo drives (and a few inverters) have the likelihood to oversee them through Step and Direction.

More Details